Product packaging is no joke. In fact, shipping and packaging are some of the largest cost factors in the total landed costs equation. Seemingly basic questions, such as how your product is palletized and how it fits on the truck, are often ignored in the design process at the entrepreneur’s peril.

Package Deal

At long last, your product has been designed and manufactured. You breathe a sigh of relief, thinking to yourself that your job is finally done. And yet…is it? Unless you’re planning on customers coming to your warehouse to pick up the finished product themselves, then you still have to handle distribution. Whether you’re shipping straight to customers or selling through a third party, you must take into account a critical aspect of distribution: product packaging. You have to put your product inside of something – to protect it, preserve it, and to make a polished impression on your customers.

In general, you should make an effort to pack your product in strong containers that are adequately sealed. Filling the package not only helps save money, but it also prevents your product from sliding around in open spaces and getting damaged. Regardless of your product’s size, ensure that the weight is evenly distributed to provide proper bracing in the container. To safeguard against environmental damage, both your packaging and your packing filler should be made of moisture-resistant materials. Perhaps contrary to your intuition, avoid writing the contents of the package or your brand name on the exterior to avoid pilferage. Using straps, seals, and shrink wrapping can also deter pilferage. Finally, be sure that you observe any product-specific hazardous materials packing requirements. It can be helpful to use a packaging checklist like the one shown below to make sure nothing slips through the cracks.

Product packaging is no joke. In fact, shipping and packaging are some of the largest cost factors in the total landed costs equation. A staggering 42 percent of insurance claims made by shippers are due to mechanical damage of products during shipping, with another 15 percent due to environment-related water and humidity damage. What’s more, the cost of goods damaged in-transit amounts to more than $4 billion annually. Clearly, inferior product packaging can cost you big-time. From a marketing standpoint, poorly-conceived packaging can also ultimately turn customers away from your product.

The good news is that you can minimize these costs to your business by designing reliable and efficient packaging. That’s why we’re here to help you understand regulatory requirements related to packaging and shipping. We’re also here to help break down the key cost factors that are a part of the packaging game. Armed with this information, you’ll be able to transform product packaging into a competitive advantage for your business (and avoid costly downstream headaches).

Learning the Ropes of Packaging

Think of packaging in a holistic, end-to-end way. Packaging considerations include everything from preparing goods for transport, to distribution, storage, retailing, and the ultimate end use of the goods. Not only do you have to consider engineering and safety components of your packaging, but marketing and branding as well. If you’re just now getting started on packaging, it can be helpful to evaluate the packaging approaches of leading competitors and other like products. Leverage their investment in internal and external resources (along with practical experience) that led to their current packaging and labeling format. However, while you can use this as a data source, keep in mind that ultimately you – and only you – are responsible for your product’s well-being, customer compliance, and legal status.

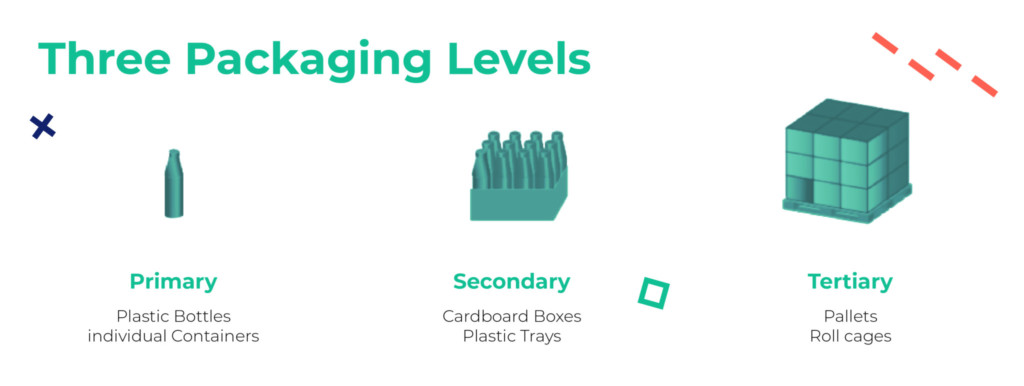

Three Packaging Levels

You’ve spent a lot of time and money making the perfect product. Naturally, you want to make sure it’s well-protected on it’s journey to the customer. Typically, this means that more than one level of packaging is needed to get the job done right. There are three main packaging levels that you should know as a hardware-based startup. The first is primary packaging, or the product’s most immediate container (think: plastic bottles, individual containers, etc.). In some cases, the primary package is kept until the consumer is ready to use the product, like in the case of a pair of socks enclosed in a plastic pocket. In other cases, the primary packaging is actually part of the product. For example, a toothpaste tube or ketchup bottle is technically primary packaging that is used throughout the life of the product. Sometimes the purpose of primary packaging is to organize or protect the product with clear bags or films – in these cases, the packaging is often called the “inner pack.”

A product with an inner pack then has to have secondary packaging (i.e. cardboard boxes, plastic trays, etc.). This is the additional layer of cover that is added to the primary package for its protection. Generally, this layer of protection is kept until the product is ready for use by the customer. For example, a tube of toothpaste usually comes in a cardboard box; the box is the secondary packaging for this product. When consumers start using the toothpaste, they will dispose of the box but keep the primary tube (often called the “outer pack”). For retail products, this is the packaging in which you see the product when it is sitting on the shelf in the store.

The third level is called tertiary packaging, often consisting of items like pallets, roll cages, or wooden crates that are needed for transit. This level of packaging is used to facilitate identification, transportation, handling, and storing of the products. In continuing with our toothpaste example, a toothpaste manufacturer may choose to send the goods to their retailers in corrugated boxes containing 10, 20, or 100 units of toothpaste. Refer to the graphic below for a visual representation of the three different packaging levels.

Unit Loads and Palletization of Loads

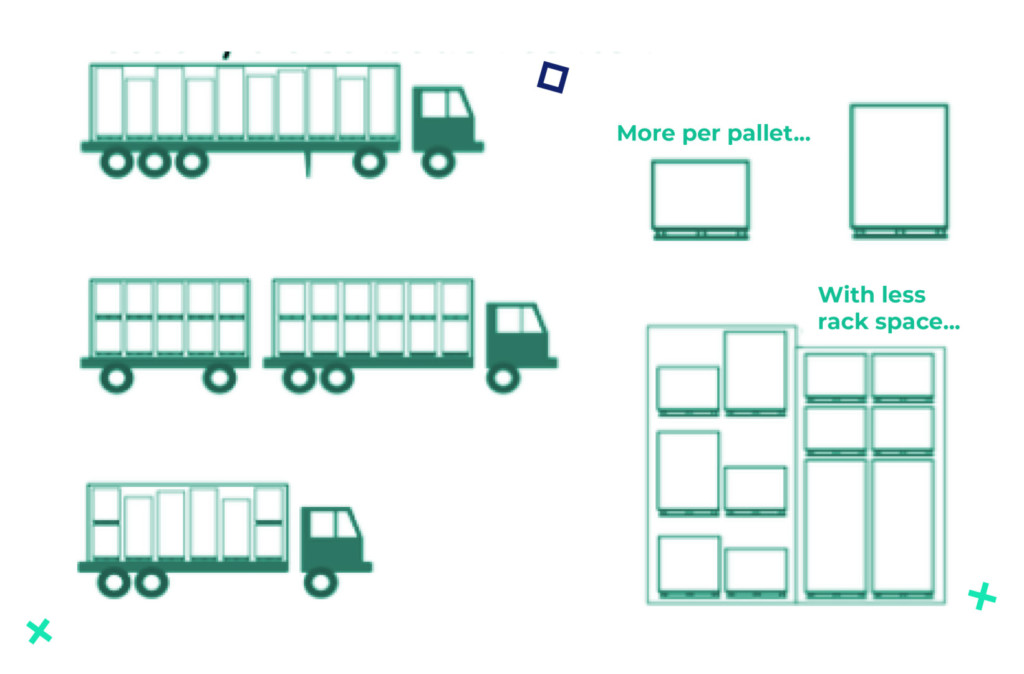

In addition to the three packaging levels, it’s also helpful to understand the concept of unit loads. This refers to a combination of products that are put together to improve transportation and the materials handling function. It includes secondary items, like cardboard boxes and plastic trays, that are used to contain primary products. It also includes tertiary items, like pallets and roll cages, which are then used to unitize secondary items. Unit loads are a key cost driver because they have downstream impacts on transport, storage, handling, and packaging. All in all, they are estimated to account for 12-15 percent of the retail sales price. The main advantage of a unit load is that it packs tightly into warehouse racks, intermodal containers, trucks, and boxcars. Yet, it can be also easily broken apart at distribution centers. The graphic below illustrates how unit loads can help improve efficiency through optimal space utilization.

Loads are commonly utilized on pallets, which allow the use of a forklift trip or similar equipment for handling. Most pallets are made of hardwood – denser and stiffer woods are preferred for durability reasons, although they can be costly. Plastic is also becoming more popular as the food industry and other sterile or particle-sensitive manufacturers are required to use plastic. The use of GPS and RFID devices, along with a greater concern for recycling, will also increase future use of plastic.

Money Talks

Given the importance of packaging, it’s no surprise that there is a price tag associated with it. You have to take into account a number of different cost factors when designing your packaging. First are customer requirements: product type and materials, functional requirements, and sales requirements. Second is the actual materials cost of the packaging itself. You also have to consider the recyclability and reusability of your packaging, determining what makes sense for both your business model and customer base. You must take into account your shipment quantities, and whether or not they are enough to require palletization. Finally, your packaging costs may also be influenced by government regulations that outline certain safety and environmental considerations.

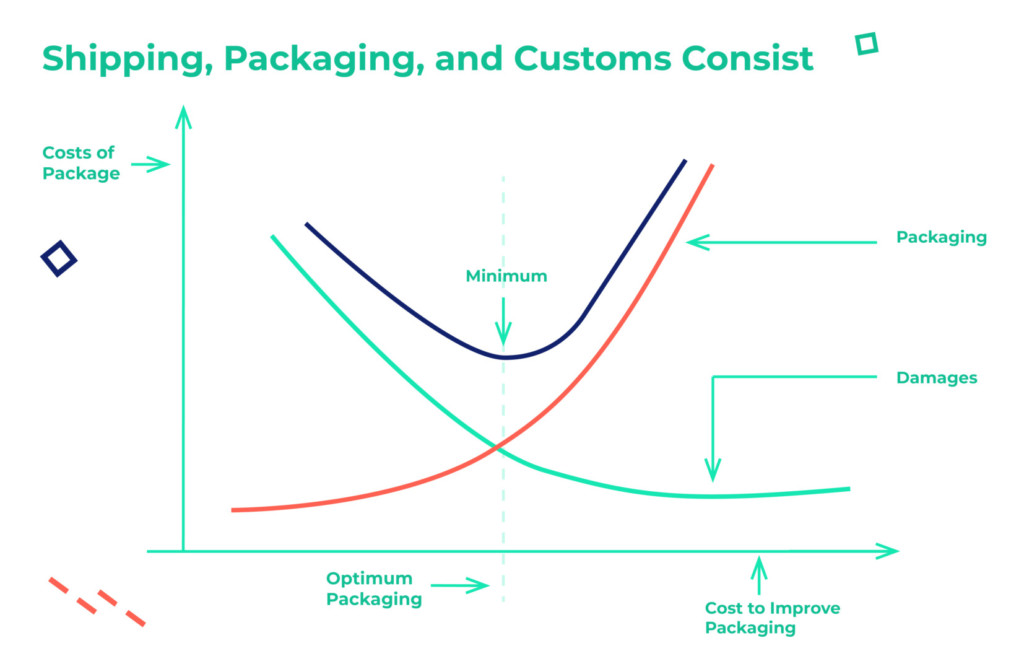

Business is all about tradeoffs, and the same holds true for product packaging. Costs can increase exponentially as you move from a low to a very low damage rate. Overall, the point where the total cost (packaging cost plus the cost of damage) is at a minimum indicates a desirable packaging design. In the graphic below, this is illustrated by the line labeled “Optimum Packaging.”

Pack Like You Mean It

Regardless of what you’re selling, product packaging is an often-overlooked key to success. Packaging design decisions translate to real, downstream costs that have the ability to affect your profitability. Not only does your packaging protect what you’ve worked so hard to create, but it also lays the foundation for what your customer thinks of your brand. Needless to say, don’t leave it up to chance.

Are you in the midst of designing packaging for your product? Sign up to receive additional information – designed specifically for hardware entrepreneurs – that will help you pack like a pro.