Hardware start-ups are challenged when moving from designing early product design to supplier engagement. Let’s be honest, most contract manufacturers would prefer to be working with more established entities. Learn best practices for engaging with suppliers, allowing you to secure fruitful contract manufacturing relationships on which your venture will depend.

Understanding the Supplier Perspective

Market research? Check. Design research? Check. Feasibility analysis and alpha engineering validation? Check, check. At this point, you’re finally ready to produce your designs. This is an exciting time in the life of a startup that involves a number of different stakeholders – some that perhaps weren’t included before this point in the process. That’s because as you consider production in a more tactical way, you realize that you can’t go it alone. Most growth-stage hardware companies don’t have the resources to handle early production needs, and therefore turn to suppliers for support.

An effective supply chain is an essential part of any manufacturing endeavor – particularly for hardware-based companies. The issue is that many hardware entrepreneurs fall victim to common pitfalls around supplier communication, selection, and negotiation that end up costing them. So, we’ve put together three lessons that outline the do’s and don’ts of engaging prospective suppliers. By understanding how to incorporate them into your overall business strategy, you can create a supply chain filled with true strategic partners.

Lesson 1: How to Communicate with Suppliers

When it comes to contacting suppliers, many entrepreneurs tend to do it “on the fly”. They don’t think through their supply chain strategy, they don’t understand suppliers’ business models, and they don’t know what to expect from an initial conversation. Why? Many entrepreneurs fancy themselves too busy to prepare for communication with suppliers. Or worse, some view suppliers as “servants” who should just execute the tasks that they are given. Best practice research indicates that this is a dangerous way to approach suppliers. You’re not selecting a servant; you’re selecting a strategic partner.

Thus, do the necessary leg work before contacting them. This includes developing a supply chain strategy that aligns with your company’s growth plan. It also includes making a list of the key questions that will help you quickly evaluate if they have the capabilities to support you. This is a two-way street, so don’t forget to prep for the questions that they will likely ask you, and align with your team in advance on how you’d like to answer them. Come prepared to the conversation with parts details (i.e. drawings and CAD files), supplier request for quotation (RFQ), timelines, target pricing, and terms. Define the control management and closed-loop feedback process that you’re looking for in a supplier.

Once you’ve done your homework, initiate communication. Take the time to introduce your company, being honest about your stage of development and funding. Set realistic expectations as to what you’re seeking with regard to quality, reliability, timeline, and costs. Don’t forget that they are selecting you as much as you are selecting them – clearly articulate the value proposition that your company can provide. How will they benefit from working with you today, tomorrow, and down the line? Finally, let them know that you are looking for a true strategic partner that you can rely on and grow with over time. Ideally, they should be looking for the same thing.

If you need to identify a list of possible suppliers but aren’t sure where to start, take advantage of the resources at your disposal. Consult local Chambers of Commerce, partner with regional business incubators, engage economic development agencies, or work with a manufacturing extension partner (MEP). Check out platforms such as VendOp and local supply chain services, like your state’s version of Pure Michigan Business Connect.

Lesson 2: How to Select the Ideal Strategic Partner

When selecting suppliers, many entrepreneurs make the mistake of always choosing the lowest bidder. While this may be cheaper in the near-term, sacrificing on quality can end up costing you in the long run. On a related note, another common pitfall is to assume that product quality is the supplier’s responsibility, rather than under your company’s management control. If quality control is indeed part of your job, do you really want to go with a low-cost supplier that cuts corners?

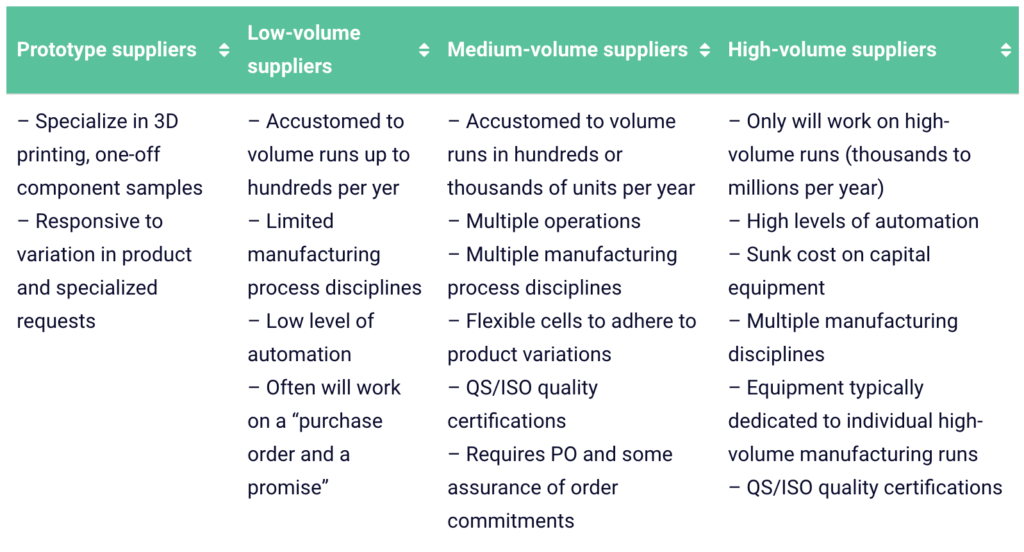

It’s also risky to assume that the supplier specializes in volume production that aligns with your scaling needs. Oftentimes, this is not the case. As illustrated below, your ideal supply chain partner fluctuates based on the volume you need to produce.

Chart Title: Supply Chain Partners: How do they change with volume?

Needless to say, selecting a supplier is a strategic decision. Hardware startups should define their most important criteria for evaluating suppliers to guide them in the process. Such criteria typically include some combination of quality, pricing, and performance. Quality can encompasses many things: expertise, quality certifications, internal processes (such as Standard Operating Procedures), part inspection, revision control, part numbers and traceability, on-time delivery, and re-work. You could even audit the supplier’s facility to confirm that they check out on all quality fronts. On the other hand, pricing evaluations are more straightforward. However, remember to take quality into account when reconciling differences in price from one supplier to another.

After establishing a quality-cost baseline, evaluate whether or not the supplier can perform your particular job. Are they familiar with your industry regulations and standards? Can their business model handle your specific volume needs? Do they have multiple sources for design materials to avoid shortages? Is the quote that they provided detailed and thorough, and does it demonstrate an understanding of your product?

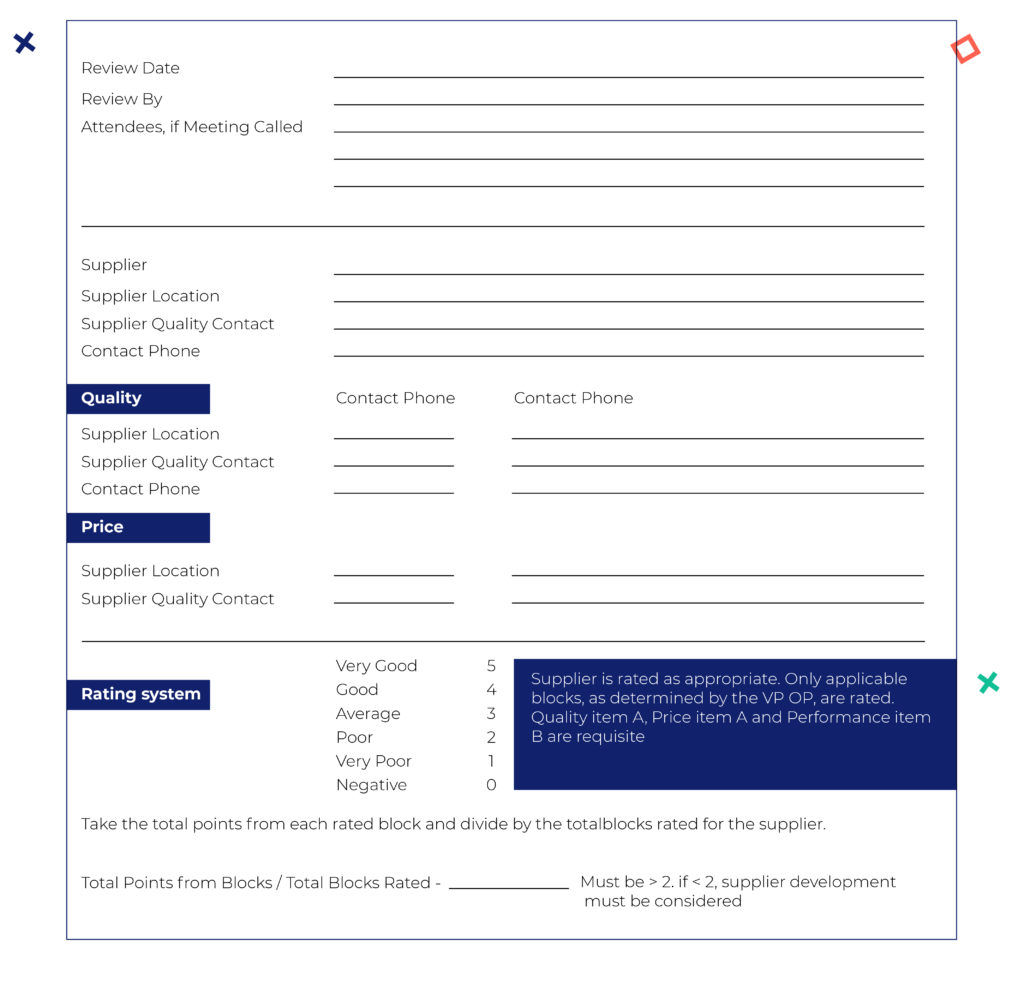

With so much to evaluate, it helps to use a scoring matrix like the example below. That way, you can compare “apples to apples” in a more objective way to make the most informed partnership decision.

Lesson 3: How to Negotiate the Perfect Deal

So, you’ve found the ideal strategic partner and are ready to do a deal. Keep in mind that this is still a negotiation – it takes a significant amount of time and money to get up and running, and your suppliers probably have other options on the table. That’s why you need a supplier negotiation strategy. This ensures that you both get the most out of the agreement and don’t overlook any areas of mutual gain.

You can incorporate five key best practices as part of your negotiation strategy. First, gain a clear understanding of the procurement terms (i.e. volume, delivery time, quality yields, etc.). What are the effects of alternative terms? Second, specify ownership with regard to quality issues (manufacturing failure vs. design failure) and tooling and manufacturing process innovation (whether it’s covered by you, them, or a combination). Third, estimate the cost of each component to ensure that suppliers are not over-charging for their services. Fourth, explore areas of mutual gain. Are there incentives that you can offer them for performance, quality, or delivery timing? Finally, develop supplier documentation ahead of time, such as service agreements, purchase orders, and payment terms and conditions. To stay organized as you prepare for negotiation discussions, create a scoring matrix like the example below to evaluate the interests of your company in relation to those of the supplier.

| Supplier’s Success Criteria | Total cost impact to supply manager (1-5 scale, 5=high) | Perceived value with supplier (1-5 scale, 5=high) | Net concession value (ranked in order of impact) |

|---|---|---|---|

| Using supply manager’s company name as a reference in marketing | 1 | 5 | 4 |

| Payment terms of Net10 | 1 | 4.5 | 3.5 |

| Initial payment received by end of quarter, ahead of product delivery | 1.5 | 5 | 3.5 |

| Weekly forecast updates provided to supplier to optimize inventory requirements | 1.5 | 4 | 2.5 |

| Limitation of liability capped to contract value for direct damages | 4 | 5 | 1 |

| Ownership of new IP developments | 5 | 4 | -1 |

A Match Made in Heaven

There is clearly much to consider as you move through the process of engaging, selecting, and negotiating with manufacturing suppliers. Done wrong, and you could end up with a supply shortage, quality issues, burned bridges, and unhappy customers. Done right, and you could end up with a strategic partner that becomes a key ingredient in your formula for success.

Want more supply chain secrets? Sign up today and get best practices sent straight to your inbox.