Most early-stage growth companies can create a technically viable prototype but struggle with engineering challenges related to cost-effectiveness, implementation, and market viability. In other words, “Cool design, but is it actually feasible?” By understanding the connection between product design and cost, you can make decisions early on that will lead to higher margins, lower costs, and sustainable growth down the line. Learn more about how near-term design tweaks impact long-term profitability.

Design Translates to Dollars

When you’re in the product design stage, your time and energy are more than likely consumed by just that – the product design. How can we make this design everything that our customers want? How can we factor these additional requirements into the product? How can we be more responsive to feedback from early customers? What many hardware startups fail to realize is that design decisions have an incredible domino effect on the rest of the value chain. More specifically, design iterations directly influence the cost model of the product (and in many cases, the bottom line of the overall business).

The critical issue is that many hardware startups lack a basic understanding of how products are engineered, manufactured, and assembled. Most early-stage growth companies can create a technically viable prototype but struggle with engineering challenges related to cost-effectiveness, implementation, and market viability. In other words, “Cool design, but is it actually feasible?” Many startups make the mistake of not even asking that question or simply push off implementation discussions until later. The thing is, “later” is too late. By understanding the connection between product design and cost, you can make decisions early on that will lead to higher margins, lower costs, and sustainable growth down the line.

Short-Run and Long-Run Impacts

At the core of this issue is a never-ending cycle of design changes. Sound familiar? Although you want to be responsive to change requests from customers, you have to first consider A) the cost of making that change and B) the impact of that change on the manufacturing process. Without doing so, you’ll face countless issues later on that can put you in the red. For instance, you could introduce a product at an unrealistically high price point due to increased production costs. You could unintentionally design a product that is too complex to manufacture and produce at scale. Or, you could eat into your margins by not fully understanding all the costs associated with your product.

When it comes to the costs associated with your product, you need to consider both short-run and long-run expenses. In the short run, you have recurring costs, which are also known as “revenue expenses”. These are the costs that your company needs to incur on a regular basis, such as raw material expenses or labor expenses. In the long-run, you have non-recurring expenses known as “capital expenses” that are not incurred on a regular basis. Once you incur these costs, they provide you with long-term benefits. Purchasing a piece of land, investing in a new building, or updating your machinery fall into this category. Finally, you also have non-recurring engineering (NRE) expenses. NRE expenses refer to the one-time cost to design, develop, and test a new product. Needless to say, NRE is typically a significant cost investment for hardware startups. What’s more, it can become even costlier if several generations of product development are needed before a product is viable for market.

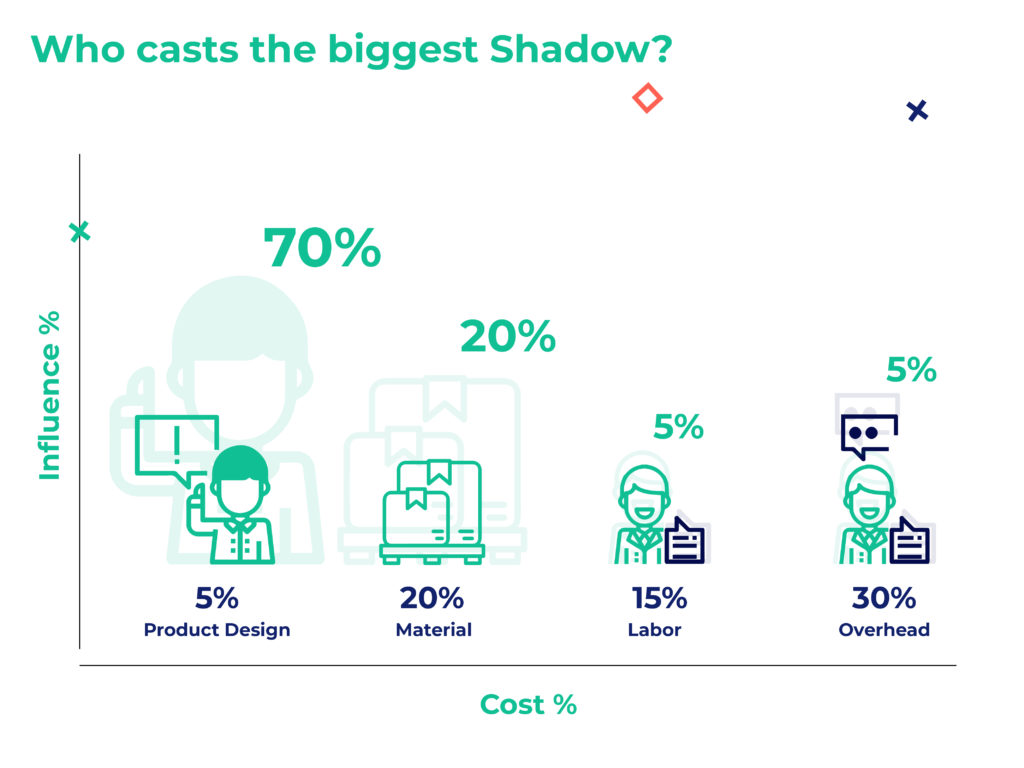

Even though product design happens earlier on in the value chain, and even if it represents a smaller portion of overall business costs, it has by far the largest impact on overall success. Your design decisions influence what raw materials are required, how skilled your labor force needs to be, what type of machinery must be used, which manufacturing processes are best, how inventory is stored, and ultimately how product is distributed to customers. As illustrated in the figure below, the “shadow” cast by product design on the rest of the value chain is not to be ignored.

Best Practices for Holistic Design

By thinking more holistically about the impact of product design on the rest of the business, startups can largely avoid unwanted, “surprise” costs. There are three best practices that you can incorporate into your business processes today to help move towards holistic design decision-making. First, establish design-freeze dates early on in the product development timeline. This means that after the specified date, no additional change requests or requirements should be incorporated into that particular product design component. It helps to curb the never-ending design cycle and focuses your team on achieving intermediate milestones.

Second, establish cost targets for your product at system and component levels. Doing so allows you to manage the cost for each individual component of the design, as well as fully understand the overall cost of your product. Oftentimes, this technique sheds light on opportunities for cost reduction that might not have been uncovered otherwise.

The third best practice revolves around competitive benchmarking. Are your competitors making similar products in a better, cheaper, or faster way? If so, what can you learn from them? To engage in analytical benchmarking, buy a unit of a competitor’s product, disassemble it, and estimate its cost. Determine how it was designed – for manufacturing and assembly, cost, performance, durability and life cycle, maintenance, serviceability, and for packaging. You may be able to uncover learnings to apply to your own product and processes that cost you little to no research and development investment.

Considering the “Should Cost”

As you begin to think more holistically about your product design, you might also consider estimating the “should cost”. Generally, this is an analysis of a supplier’s expenses involved in delivering a product or service. Although it assesses figures provided by suppliers and is often used in negotiation discussions, this approach can also help your team assume a more holistic design mindset. To estimate the should cost, engage your own team as well as external experts to rethink the design of your product. If you were in your supplier’s shoes, ideally what should it cost to manufacture your product?

This exercise might help your team make a connection between the design and production costs that are higher than they need to be (thus leading to deteriorating margins). If this is the case, brainstorm ways to reduce cost based on design. Can you replace expensive materials with something more cost-effective? Is there a way to reduce expensive tooling, or decrease part count? What effect would in-line testing have? Can you reduce assembly steps? Thinking through these kinds of questions may lead to an “aha!” moment from a design perspective that will ultimately improve profitability.

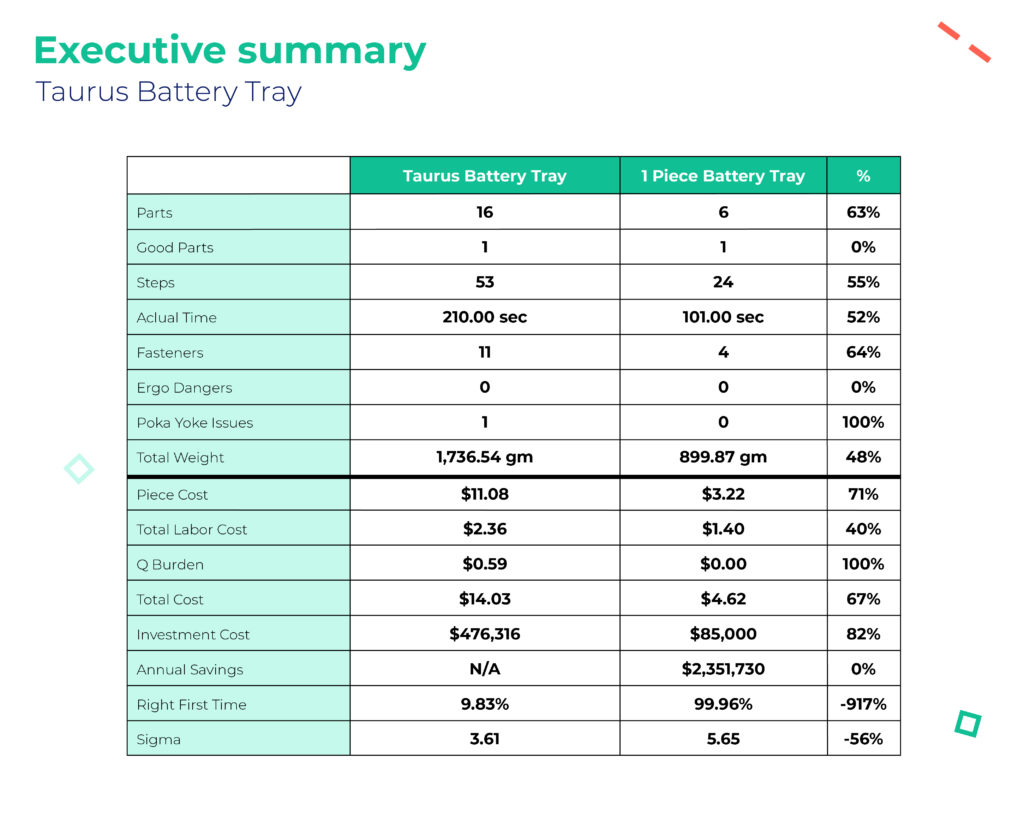

Consider a should cost case study example relating to a vehicle battery-pack tray. The initial vehicle battery tray consisted of three separate metal parts with a number of individual fasteners (J-nuts, weld nuts, and bolts). However, by converting the battery-pack tray to a single piece of molded plastic, the company was able to achieve incredible benefits. Material costs decreased by more than 70%, labor costs decreased by 40%, and the manufacturer estimated an annual savings of over two million dollars as a result of this modification. That’s huge! Refer to the table below to see the full impact that this simple design change had on the bottom line.

The Product Design Domino Effect

The decisions that you make with regard to product design do not exist within a silo. For better or for worse, they produce a domino effect that cascades throughout your value chain and trickles down to your bottom line. By fully understanding how design tweaks impact business costs, you can make more informed decisions that ultimately lead to higher profits in the long run.

Want to learn more about the relationship between product design and financials? Join our community of hardware entrepreneurs and get content like this delivered directly to your inbox.